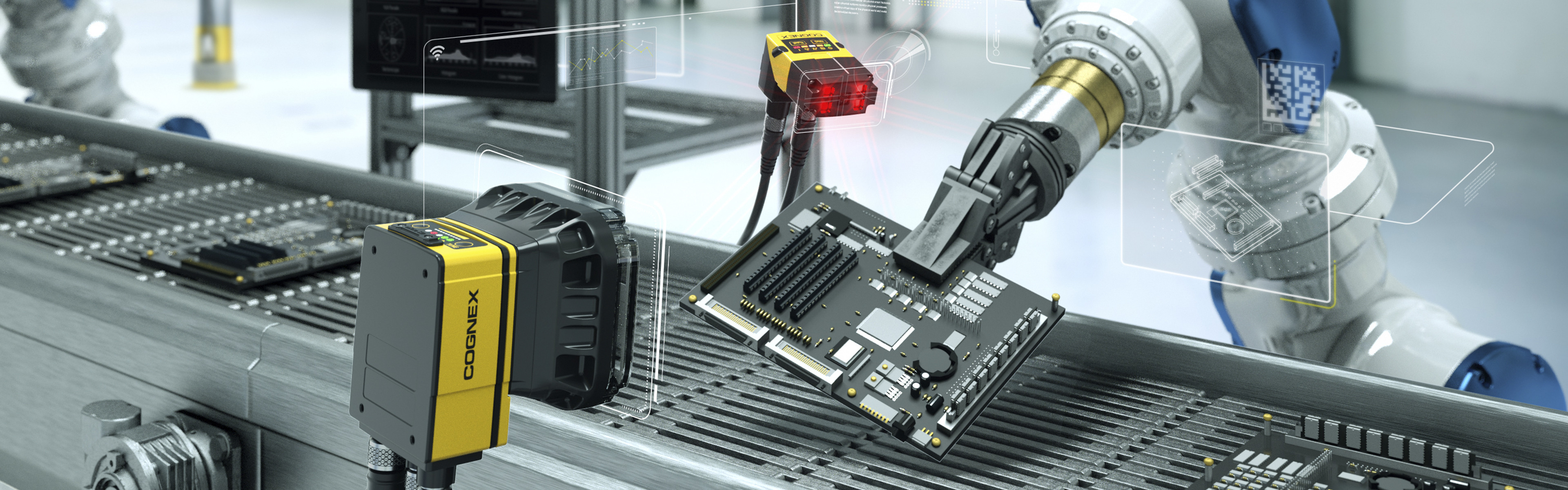

Industrial robots, cobots

Increase productivity on production lines.

Today’s global market is highly competitive and it is becoming increasingly difficult to achieve a high quality product or service while reducing costs. Therefore, more and more companies are choosing to use automation in the form of industrial robots. Thanks to them, the efficiency of production processes is increased, and it is possible to combine production stages by replacing, for example, several devices with a robot.