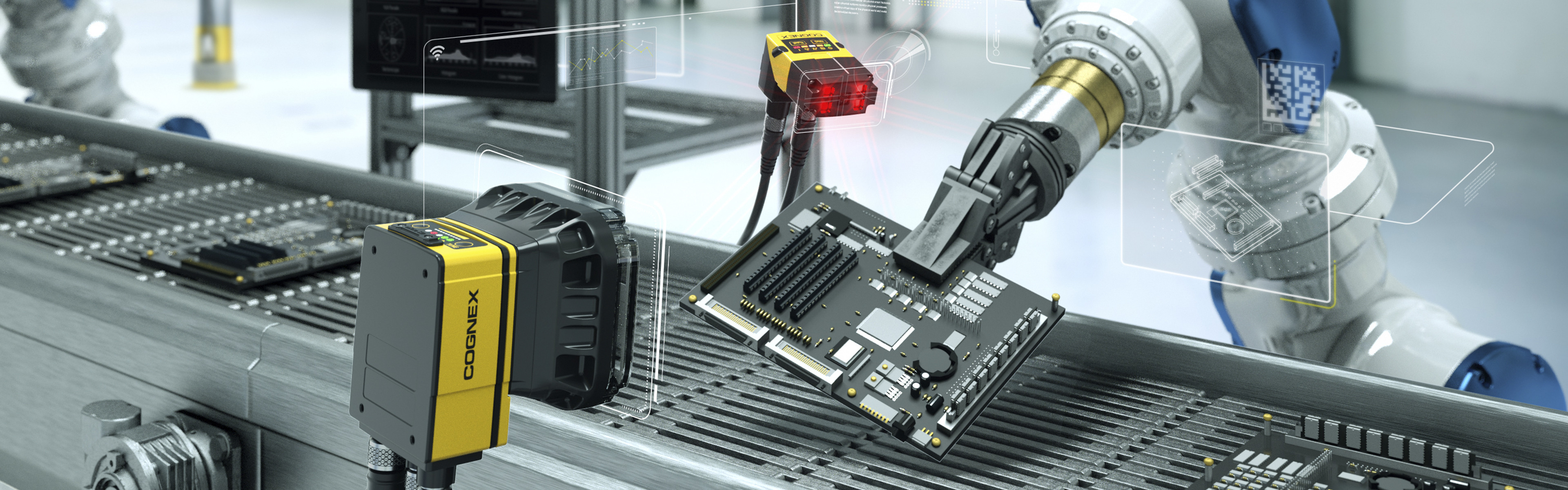

Modernization of machines and production lines

Solutions that guarantee the safety of work areas.

Based on many years of experience, we modernize machines and production lines, both in terms of safety and functionality.

Based on many years of experience, we modernize machines and production lines, both in terms of safety and functionality.

Our work ranges from design to implementation. The experience gained allows for precise planning of deadlines and implementation times and their subsequent keeping. When establishing the concept, we take into account not only the assumptions presented by project managers, but also the convenience of operators, ease of repairs performed by maintenance and the satisfaction of the accounting department.

The experience gained while performing safety audits allows for the modernization of devices in accordance with all standards and directives. An interdisciplinary team of specialists is able to carry out comprehensive, extensive modernizations including such works as:

Modernization of machines in terms of functionality:

Machine modernization in terms of safety:

Examples of modernizations carried out by our team:

| Modernization | Comprehensive modernization of the technological line control system Scope of work:

|

Building materials industry |

| Modernization | Comprehensive modernization of the technological line safety system Scope of work:

|

Electrotechnical industry |

| Modernization | Modernization of the production line by changing its course and adding new functionalities Scope of work:

|

Pharmaceutical industry |

| Modernization | Modernization of the product packaging line by changing its shape in order to reduce the occupied space: Scope of work:

|

Pharmaceutical industry |

| Modernization | Modernization of machines in terms of safety Scope of work:

|

Automotive industry |

| Modernization | Modernization and renovation of the boring machine Scope of work:

|

Automotive industry |

Experts in Safety ● Automation Engineering

Automatech Sp. z o.o.

ul. Ewy 2, 05-816 Opacz - Kolonia, Poland

Our sites

Realization: ReklamaSem