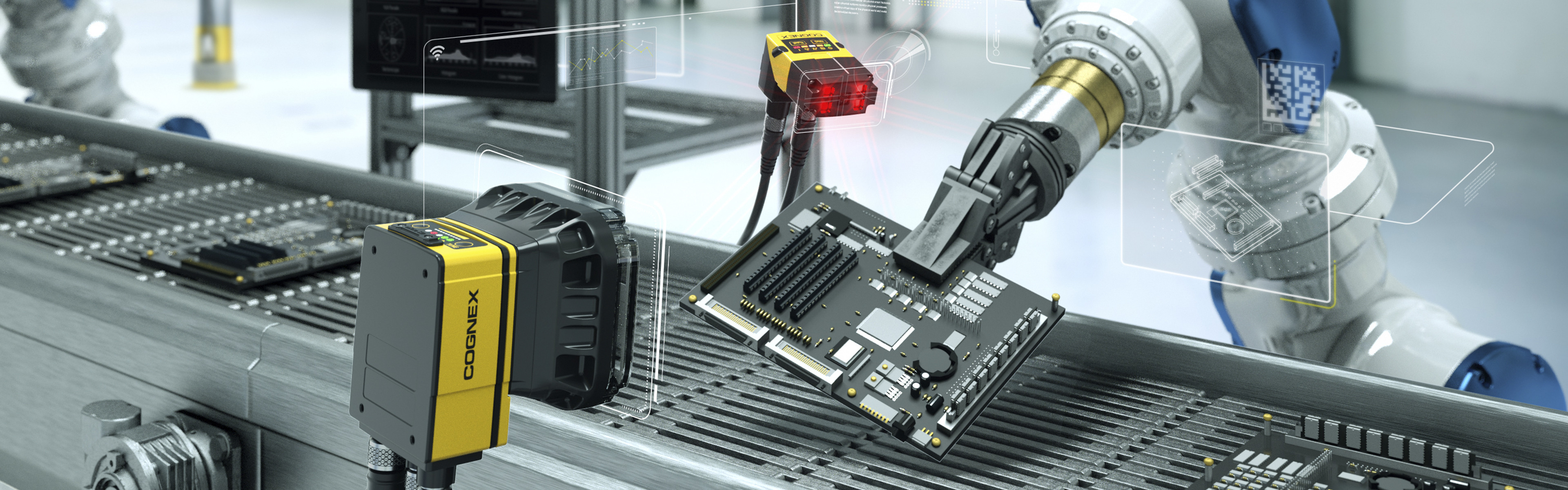

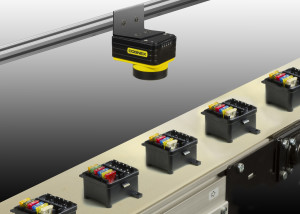

Vision systems

Industrial vision control market.

The vision control systems industry has been growing rapidly from many years. The basis for this development is the requirements of the industry: stricter quality standards, automation of processes, minimization of errors, recording of inspection results in databases. Therefore, at the base of many production lines, you can find a vision system, which is a control of product quality.